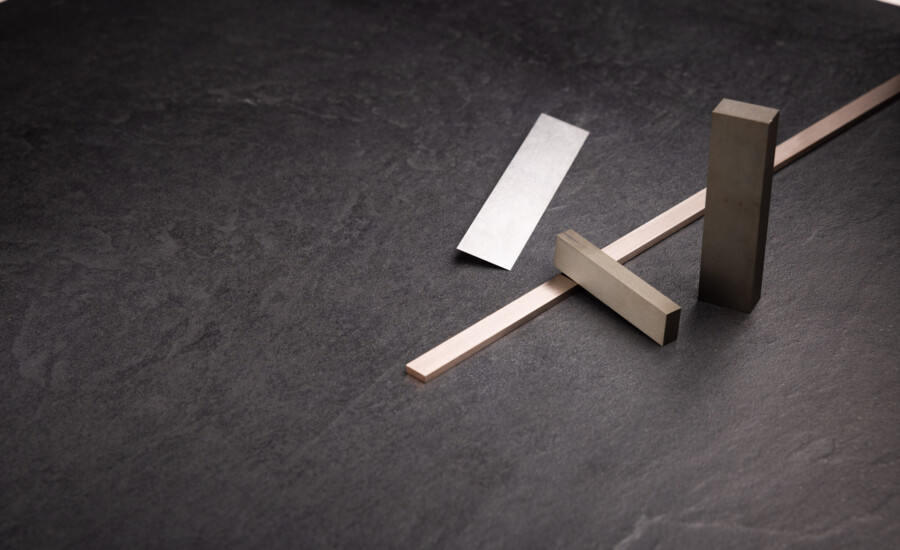

Refractory metal sheets & alloys

Sheets, plates & foils in standard dimensions or made to measure

Sheets, plates and foils from Litty are indispensable components for industry and production technology. Special applications are made possible through the special properties of high-melting-point metals and their alloys in composite materials. High melting points of up to 3,422 °C ensure proven results and groundbreaking innovations. Are you looking for sheets made of refractory metals and alloys?

Metals & alloys

Learn more about the specific properties of each metal

- Tungsten sheets

- Tungsten-copper sheets

- Tungsten heavy metal sheets

- Molybdenum sheets

- TZM alloy sheets

- Tantalum sheets

- Niobium sheets

- Custom-made products

Metal sheets made of refractory metals can be varied as desired in terms of dimensions, tolerances and alloys and obtained from us. We’re happy to respond to your requests quickly and flexibly!

The areas of application

Tungsten and tungsten alloy metal sheets are used for many industrial applications depending on their strength:

- High-temperature furnace linings

- Reflectors for lamps

- Shielding of X-ray or radioactivity radiation

- Shuttles for vacuum coating

- Compensation elements in aerospace

Indispensable: Tungsten in industry

The properties of tungsten – in particular its high boiling and melting point of 3,422 °C and its high density of 19.25 grams per cm³ – bring precision to manufacturing and provide advantages in many industries. Whether tungsten is used as a flywheel mass, counterweight or vibration damping: in aviation, automotive, sports and telecommunications technology, tungsten and products made of tungsten alloys are indispensable. In addition, tungsten is used in medical technology and as a substitute for lead.

FAQs

Tungsten has the highest melting point of all metals – it has a melting point of 3,422 °C. Tungsten is irreplaceable when high temperatures stress the material. At temperatures between 1,000 and 1,600°C, semi-finished products obtain their basic shape by means of forging, round hammering or rolling. Work pieces with very low tolerances can be manufactured by a subsequent surface grinding operation.

Alloy additives can be used to influence the chemical, physical and mechanical properties of our semi-finished and finished parts. Depending on the required application, an alloy can be chosen that has optimal parameters in terms of resistance, interaction, temperature behaviour, material properties, conductivity and machinability.