Refractory metals in the automotive industry

Trendsetting developments for people and vehicles

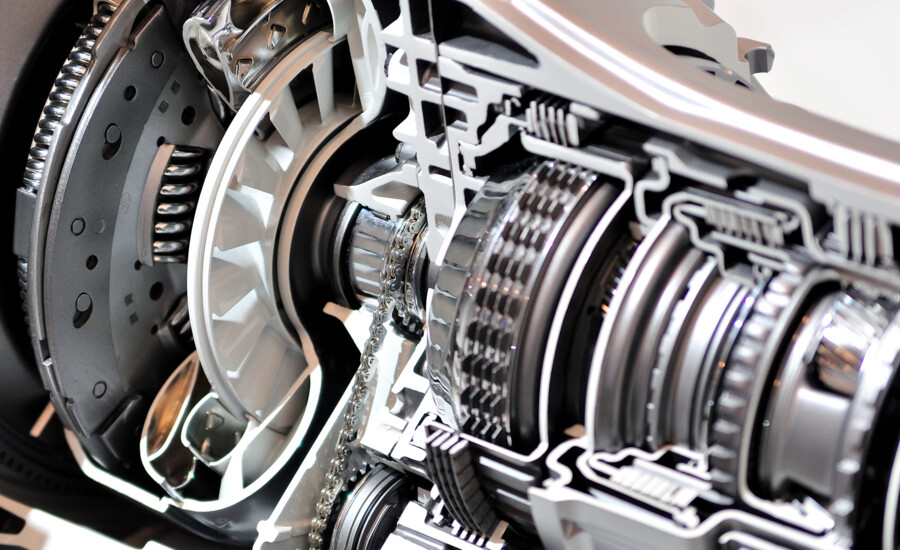

At Litty, we care as much about technical excellence as we do about customer satisfaction. Many of the great advances in modern automotive technology are due to refractory metals such as tungsten, tantalum, niobium or molybdenum. The use of these raw materials in pure or alloyed form is indispensable for the automotive industry and its suppliers. Refractory metals are used above all in the field of engines, where components have to withstand high thermal and mechanical stresses. Trendsetting car brands have always relied on the advantages that refractory metals make possible.

Use of refractory metals in the automotive industry

Refractory metals such as tungsten are used, for example, in the construction of spark plugs, glow plugs, combustion chambers or turbine blades. They are also found in exhaust systems, as they can withstand high temperatures well and help to make exhaust gases cleaner and more environmentally friendly.

Overall, refractory metals in the automotive industry help to make engines and exhaust systems more powerful and durable. They make it possible to produce parts that have to withstand high temperatures and at the same time are lightweight and resistant. In car racing, for example, tungsten plates serve as special “balancing elements".

Good to know

Did you know that tungsten is also found in electric cars? A British research team is working on a solution to charge electric cars ultra-fast. Their “magic alloy” is called niobium-tungsten oxide. If this is used instead of graphite in the anode, the ions are supposed to become more “mobile”, which accelerates the charging time enormously: namely to 90 percent in five minutes.